This is a photo I took of the new sliding storage shelves in our storage room. Each rack had its own type of item, for example: bottles on one shelf, tubes on another, tissue culture treated flasks on one and so on.

Each shelf was customized to fit the different sized boxes that each consumable was delivered in, in order to use the space as efficiently as possible.

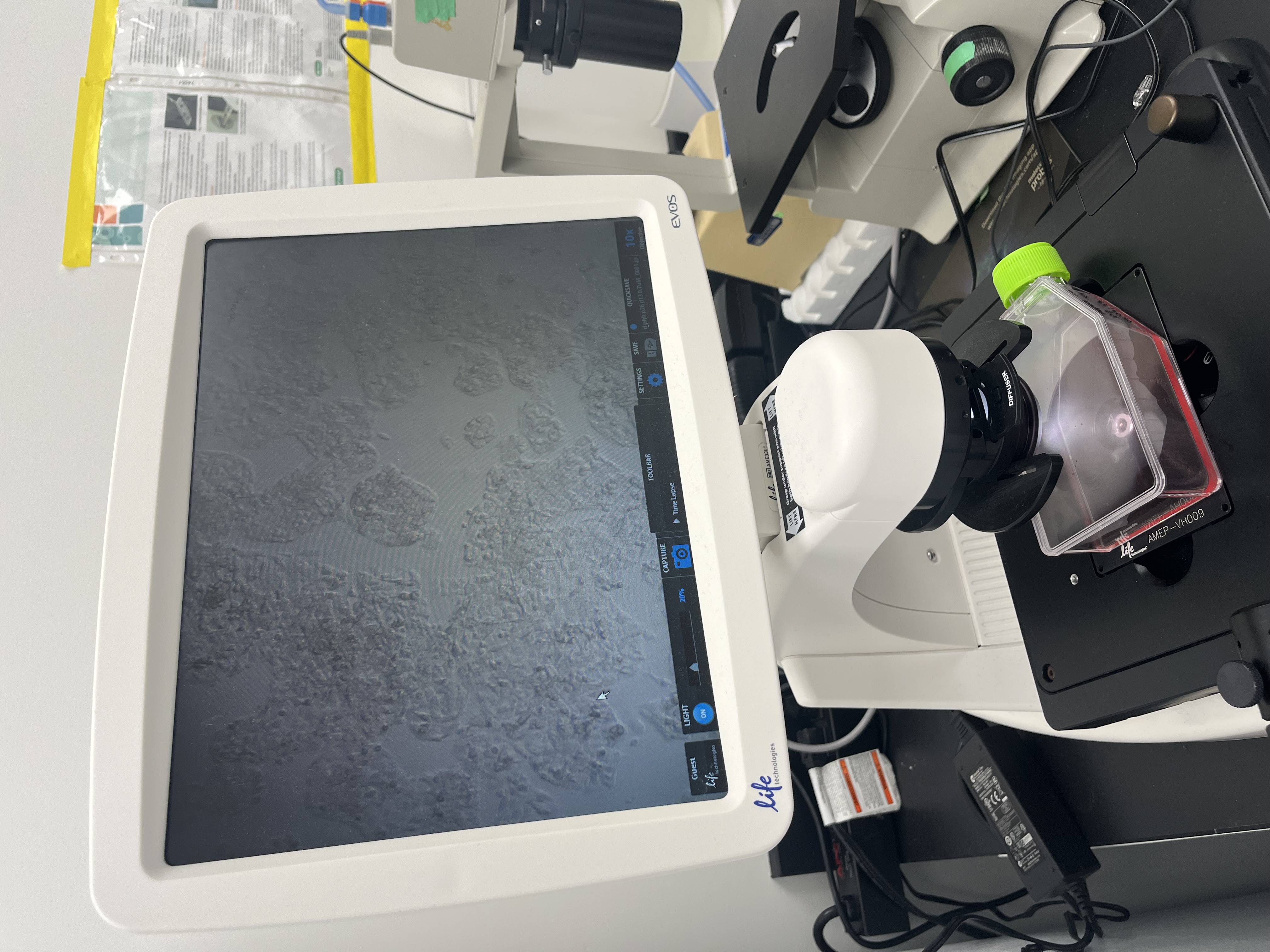

Hep G2 is a liver cancer cell line that grows in “island like” formations. These cells are kept in a flask that has been treated for cell culture, in order for cells to adhere to the flat surface. The pink liquid or cell culture media, may contain antibiotics, vitamins, buffers and serums (depending on the type of cell line) this helps keep the cells healthy as they grow.

This picture shows a high density of cells which have adhered to the flask. Passaging cells is when you harvest cells from one culture and transfer them to a new flask with new medium, in order to start new cultures.

Cells that are in these flasks can then be cryopreserved (stored in Liquid Nitrogen for long term storage) or a protocol for protein extraction can be followed to run a variety of assays (an investigative procedure) on the sample.