Orientation and First Weeks

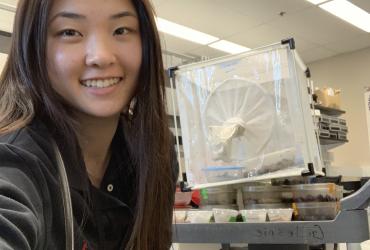

Prior to officially starting my work term at SFU FCREL, I had a couple of training orientations with the previous co-op student. They demonstrated how to assemble different cell fixtures and how to operate the computer software for testing. Having a notebook to jot down key steps and important notes helped me remember how to complete tasks such as setting up experiments. This helped me significantly in the following weeks after I started, as I was still getting the hang of things. The researchers were patient and understanding during the learning phase. I was also sent some thesis research papers that provided detailed information about the fuel cell experiments, which helped with understanding the purpose of the experiments. Orientations with various researchers about their fuel cell experiments deepened my knowledge so that I was able to understand the purpose and goal of their tests.

Day to Day

General Tasks

When I arrive at the lab, I check the hydrogen and nitrogen gas supply to ensure that there is enough for experiments to run. The hydrogen and nitrogen gas supply usually lasts for one month before they have to be changed and when they are changed I ensure to follow safety protocols in handling gas cylinders. I also keep track of when they are changed so that I have a record of when they were last replaced which helps to determine the next time they are to be replaced. I frequently send orders and request quotations for items in the lab and ensure that the lab space is tidy and that the tools are where they belong. When the test stations have a problem, the other researchers and I, collaborate to resolve the issue.

Experiment Tasks

The most common task I complete day-to-day is setting up cell fixtures, which consists of precisely cutting gas diffusion layers that are placed inside the cell fixtures to speed up the reactions during the test. Another task is to connect the gas tubings, thermocouples, heaters, load bank wires, and potentiostat cables for diagnostics. But before connecting all the wires, we need to test if there is a gas leak with the cell fixture by connecting the inlet and outlet tubings first and flowing some nitrogen and hydrogen. Then we use a leak detection liquid compound to test for leaks in the tube connections and a sniffer device that detects combustible gases like hydrogen near the connections. Once these leak tests are completed, the scripts can be loaded, and the cell can be conditioned and tested through the scripts and the automated station. After the experiment is finished, the researchers or I will analyze the diagnostics. The potentiostat helps run diagnostics and consists of cyclic voltammetry, polarization curve, electrochemical leak detection test, linear sweep voltammetry, and electrochemical impedance spectroscopy. These diagnostics can help us determine whether the cell has met the failure criteria and if the membrane has deteriorated.