Within my project, I am analyzing the durability of polymer electrolyte membranes (PEMFC). PEMFCs are one of the most attractive technologies regarded to replace fossil fuels in transportation and stationary applications due to their high performance, efficiency, and zero toxic emissions. The ionomer membrane is the key component in PEMFCs. It is responsible for conducting reactive ions between the working electrodes while electronically isolating the electrodes from each other. During the fuel cell operation, the ionomer undergoes extensive chemical and mechanical stresses due to repeated shut-off, start-up, and rapid fluctuations in temperature and humidity. During my time working at FCReL, I had the opportunity to work with some of the most advanced processing and fabrication techniques. These include Dynamic Mechanical Analysis (DMA), Laser Cutting, and Simulation work.

DMA

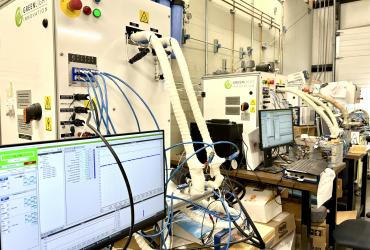

Using the TA Instruments DMA 850, I measure the tensile stress of PEMFCs at different conditions of temperature and RH from ambient up to operating conditions. A specimen is taken from either the machine direction or transverse direction and is placed in the DMA instrument, then the sample is elongated at a user-defined strain rate until it fails or reaches the end of the capabilities of the instrument. I then calculate yield stress and Young’s Modulus of the sample using Excel. These values are used extensively in simulation work and performance testing on fuel cell test stations.

Laser Micromachining

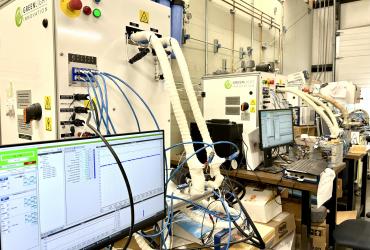

This position at FCReL has given me the unique opportunity to work at SFU’s state-of-the-art processing and fabrication facility, 4D Labs. They are located on the 7000 level of the Technology & Science Complex Two (TASC 2) at the SFU Burnaby campus. At this facility, they host the IPG IX-280-ML laser workstation with an excimer UV laser that emits ultraviolet radiation in the 193nm wavelength. The tool has a maximum beam pulse energy of 9 MJ, and the beam dimensions are 2mm x 6mm (width x height).

This is ideal for micromachining because excimer lasers can produce a very small, precise pulse of UV at small wavelengths. They are excellent at removing material through ablation since it can precisely remove the material with little to no buildup of heat. Excimer lasers are also used in the process for manufacturing semiconductors with photon based optical lithography. I use this tool to cut the precise components necessary for the small-scale fuel cell testing assembly. These components included: Kapton with Teflon, catalyst-coated membrane (CCM), and gas diffusion layer (GDL). In my experience, ionomer material is very susceptible to burning so I appreciate how easy it is to adjust the laser power and processing parameters using the computer interface. During my first visit to the laser cutter, my CCM caught fire, and the entire sample was destroyed completely. To avoid burning my CCM a second time, I decreased the laser power and pulse width while increasing the processing speed.

Our research group pioneered the use of the small-scale assembly in combination with X-ray Computed Topography (XCT). It is an exceptional method to analyze cell degradation after cell conditioning and multiple operational cycles. Our cells are subjected to multiple accelerated stress tests (AST) until performance metrics drop below predetermined levels. Afterwards, the entire assembly including the graphite electrodes, Teflon gasket, and 3D-printed housing will be transferred into the XCT machine without being disassembled because disassembly would disturb the cell. Surprisingly, the XCT equipment we operate is very similar to medical CT technologies.

COMSOL Simulations

Along with DMA experiments, I have been tasked to create a material model for the ionomer membranes using finite element analysis. To complete this task, I build the model using COMSOL Multiphysics to simulate the properties of the membranes under similar environmental conditions. One of the special perks of working in this position is the state-of-the-art computing resources I have been provided with. These are in the form of commercial software licenses and supercomputer access at SFU Cedar. When I first started, I had no idea how to work with COMSOL or its capabilities. By the end of my work term, I have developed a baseline model considering the physics and material types for modelling the stress-strain curve of the ionomer by inputting material properties and specifying environmental conditions. Within this section, I have been examining different material models available in COMSOL. These include St Venant Kirchhoff, Gao, and Ogden. However, COMSOL’s built-in material models do not accurately model my ionomer material so, I ended up developing my own material model with the Three Networks Model Theory. Furthermore, to improve the computation time of my model I have implemented a user-defined mesh where the center portion of the membrane has larger triangles and the edges have smaller triangles. Doing so does not decrease the accuracy of the model since most deformations happen on the edge and the center can be approximated.

Through completing my daily tasks, I developed an interest in laser technology, simulations, and mathematical modelling. I have taken the knowledge and experience that I have gained while working at FCReL to do some personal projects that include physics simulations and working with lasers. For example, I laser engraved a cat image into birch plywood.