Orientation and First Weeks

An orientation was held at the beginning of the term with co-op students from all the departments, including Integrated Planning, Operations, Finance, and Cybersecurity teams. Guest speakers from multiple departments presented about safety, business rules, and working environment adaptation. The CEO of BC Hydro also joined the virtual meeting and shared his career experience and growth. It felt great to have an interactive orientation and make connections with the team.

In the first weeks, my supervisor helped me get access to various corporate platforms and signed me up for online learning courses to get familiar with the work. The most impressive training is the cybersecurity one since that session helped me understand the significance of managing cybersecurity risks to our power systems. Besides the training, I also spent time connecting with other colleagues and understanding the job of different teams.

In addition to the online virtual training, the in-person Power System Safety Protection training was informative and interactive. The instructor explains the process of performing work at power transmitting stations with vivid scenarios. This training is more than a requirement for employees and contractors to access the power system. It tells us how to protect ourselves and public assets with proper procedures. Besides the training I participated in, BC Hydro has other learning resources and events to help staff develop skills in information technology, indigenous culture, and environment protection fields.

Learning and Adaptation

The team I work with focuses on equipment that has PCB contaminant risk. PCB stands for Polychlorinated Biphenyls. Electrical equipment such as transformers, capacitors, and circuit breakers with insulating fluids manufactured and installed before 1986 can contain PCBs. Since the last century, many studies have recognized PCBs' potential risk to the ecosystem and physical health. After the implementation of strict PCB regulations, BC Hydro started to remove equipment with concentrations of 50 parts per million or greater from the power system to meet an Environment Canada phase-out deadline of December 2025.

I was not completely aware of these environmental hazards until I got on board with this co-op job. Now I see how much effort BC Hydro has invested to mitigate the impact of PCBs. By learning the business rules and shadowing project managers on the team, I gradually got familiar with the sampling, testing, and equipment phasing-out process.

During the study in Sustainable Energy Engineering, our goal is to minimize the environmental impact of industrial practices such as generating and transmitting power. The connection between my program at SFU and my co-op experience motivates me to learn more about these projects.

Accomplishments and Challenges

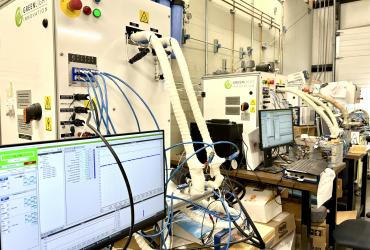

In the first co-op term, I supported the hydraulic oil sampling and testing work which had been initiated. This job involves coordination with the station field crews and Powertech Lab chemists. Powertech is one of the two subsidiaries of BC Hydro. It supports many BC Hydro projects in the field of testing and research. The process of getting PCB test results from the lab chemists is not as smooth as I expected since the lab systems are not connected to BC Hydro's systems. On the field side, multiple work orders were carried over due to sampling difficulties and it's hard to track samples. To improve the connection, I contacted the field technicians and checked the status of each sampling work. After communicating with the field team, we know more about the sample delivery time and tag details. The chemists from Powertech Lab could identify and analyze the exact samples with the information we provide.

The active communication with the station field crews helped me with the Generation site Distribution-class equipment PCB verification project that started in the second term. With the help of the engineers and electricians, I got more information about the equipment such as type, manufacturing year, and recent maintenance. Their proficiencies with the equipment save me a lot of time from searching around multiple asset management and tracking systems.

Besides the work related to PCBs, I support other teams in the department as well. The most challenging one is about asset detailing of replaced equipment because there are multiple stakeholders to coordinate with. Asset detailing is a significant process for capital replacement projects. We provide the physical and financial asset record when the installation of the new asset is completed. Proper asset detailing ensures that asset inventory has accurate information about the specific equipment.

I learned that nothing is perfect in the complex project world. My mentor has been a project manager in the utility industry for decades. He taught me how to seek solutions while encountering problems or deficiencies with a patient attitude.

Cultural and Environmental Observations

Compared to my previous co-op experience, my working content now is focused on projects instead of individual tasks. Within an integrated team with strong connections with the industry, I am becoming part of the collaborative workforce.

At the beginning of my co-op term, I assisted my program manager with building the outage schedule related to the transformer bushing replacements for the next year. This work is more challenging than I expected. From supplying the material to fit the availability of the contractor team, all the coordination requires proficiency with the process and familiarity with the power system.

In the last few months, I joined two year-end review sessions with the contractor groups. Observing how the program managers summarize the work from multiple perspectives is inspiring. The consideration of safety, scope, and budget is comprehensive. With the analysis of units and financial data in the past fiscal year, the team reviewed the work performance quantitatively and brought in lots of ideas to meet the expectation for future projects.